printable version printable version

Check turbocharging system for leaks

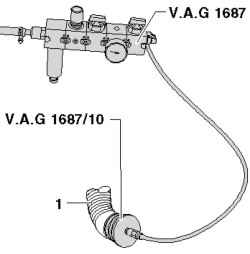

Remove the air intake hose from the air filter 1. Vstavteadapter 1687/10 sleeve inlet 1 and to fix its collar.

Prepare supercharging systems tester VAG 1687 to perform check (Fig. 2.223).

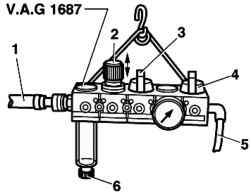

Fully unscrew the pressure regulator valve block 2 and 3 and 4 (Fig. 2.224).

NOTE To rotate pressure regulator knob 2 it is necessary to pull up. |

Connect tester for turbo VAG 1687 as shown in Figure 2.223. Connect the compressed air source 1 (line or compressor) Systems Tester VAG 1687 supercharging.

NOTE If the glass is collecting water, pour it through a drain plug 6. |

Open valve 3. Use the slider to set the pressure of 2 to 0.5 bar.

ATTENTION The maximum pressure must not exceed 0.5 bar. Higher pressures can cause engine damage. |

Open valve 4 and wait until the circuit is filled with compressed air. If necessary, re-adjust the pressure of 0.5 bar. Search for the leak listening and passing his hand near the suspicious places. In addition, you can use spray or leak detection device for collecting ultrasonic noise VAG 1842.

NOTE Minor leakages are permissible in the turbocharger intake, since the suction hoses are not designed for overpressure. A small amount of air flows through the valve into the engine. For this reason, can not check the residual pressure. |

Operation of the device to capture the ultrasonic noise VAG 1842 By eliminating leaks found Follow the instructions for the installation work in the pressurization system. Before removing the adapter, relieve the pressure in the circuit, removing the sleeve from the adapter 1687/10.

Installation of hose connections with the nipple connectors

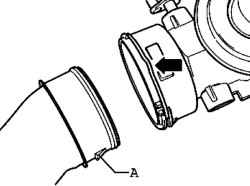

ATTENTION O-ring choke connector may be damaged if the retainer bracket-installation is in the locked position. The result is a leak. Follow the installation instructions. |

Withdrawal

The socket connector can be unlocked by pulling the clip-lock (Fig. 2.225). Disconnect the hose / pipe should be without any aids.

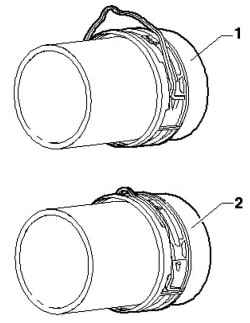

Setting When replacing the O-ring groove in the coiled hose for charge air. Note that the ring is fully seated in the groove. Lightly grease a working edge of a sealing ring with engine oil. Give the bracket latch to the unlock position 1. Vdaviteshlang supply charge air all the way into the slot.

| Fig. 2.226. The provisions of locking and unlocking the lock

|

Priveditefiksatornuyu bracket in the locked position 2 and push the hose again completely (Fig. 2.226). By pulling, check for correct seating and reliability of fixing the hose coupling.

Turbocharger Check the air filter housing, the filter element and intake hoses for dirt.

ATTENTION If the turbocharger detected mechanical defects, such defective impeller, not enough to replace the turbocharger. To avoid future defects included the following. |

Check the entire delivery unit and charge air cooler charge air for the presence of foreign objects. When they identify the entire assembly must be cleaned charge air supply and charge air cooler, replace if necessary.

NOTE All hose connections must be secured. The supercharged system must be airtight. Self-locking nuts must be replaced. Before screwing the oil supply line to the engine oil fill coupling turbocharger. After installing turbocharger run the engine about 1 minute at idle. Do not increase turnover dramatically immediately after the engine starts. This ensures lubrication of the turbocharger. Observe security measures. Observe rules for cleanliness. |

|