printable version printable version

Check and adjust the position of the pistons unit injectors

Test condition The motor must be dismantled.

The order of execution of works Remove the soundproof cover and cylinder head cover corresponding cylinder head. Remove the fuel pump or tandem respectively. Cylinder head Crank the engine with the help of counter support - T10172 TDC and remove vibration damper. Install lock crankshaft T10195.

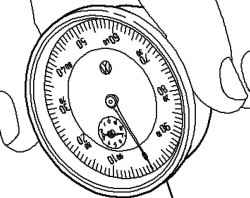

Set the dial gauge a set of VAS 6341 with a universal tripod VW 387 and create a pre-stress of about 1 mm on the disc springs injectors as shown (Fig. 2.288). Remove the crankshaft locking pin T10195 and scroll engine against the working direction of rotation until the arrow until the indicator stops moving. Set the dial gauge to "0". Crank the engine in the operating direction of rotation up to TDC and reinsert locking pin retainer crankshaft. Read the measured value on the display.

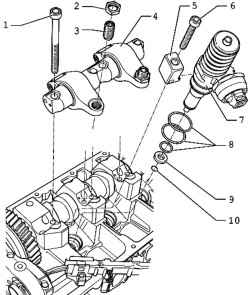

| Fig. 2.289. The components of the unit injector: 1 - a bolt 20 Nm + to tighten on 1/4. (90 ?°); 2 - lock nut, 30 Nm; 3 - the adjusting screw; 4 - axis roller levers; 5 - spacer; 6 - a bolt 12 Nm + to tighten on 3/4. (270 ?°); 7 - unit injector; 8 - O-ring; 9 - heat-insulating seal; 10 - a lock ring

|

Setpoints Engines AYH, BKW: 5.18 mm ?± 0.1 mm. Engines BLE, BWF: 4.95 mm ?± 0.1 mm. If the nominal value is reached Assamble engine. If the pressure setpoint is not reached, remove the external cover of support A, set the jig T10199 gear on the camshaft and tighten the device with 40 N ?· m. Loosen the camshaft sprocket mounting bolt head T10198. Scroll head camshaft T10336 to reach a predetermined value. Tighten the camshaft gear torque of 150 Nm and repeat the measurement. If the specified value is obtained, tighten the camshaft sprocket mounting by 90 ?°. Install the cylinder head cover and sound insulation cover.

NOTE Always replace gaskets and O-rings. |

|