printable version printable version

Removing and installing oil pan

Withdrawal Drain the engine oil.

NOTE Observe proper disposal. |

Disconnect the connection pipe to the compressor air suspension on the air filter. Remove the air filter assembly from the flow sensor. Turn off fixing nuts 2 on the left and right engine mountings. Insert Traverse 10-222 A - adapter 10-222 A / 16 high side guide spindle up. Plug adapters 10-222 A / 19 in Traverse 10-222 A right and left. Install yoke 10-222 A on spars. Pick up the engine two earrings 10-222 A / 12 - to the adapters 10-222 A / 16 - and gently pull it. Remove the sub-frame. Remove the motor mount. Air leaving the motor attached to the motor mount. Disconnect the 3-pin connector of the level sensor and engine oil temperature G266. Remove the oil pan mounting. If you want to separate the oil pan, flip through it with a rubber mallet. Remove residual sealant on the cylinder block with a flat scraper.

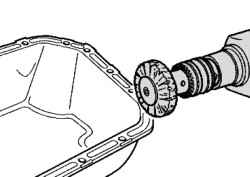

Remove residual sealant on the oil sump with a rotating brush attachment, such as a hand drill with a set of brushes, nozzles with plastic bristles (wear protective goggles) (Fig. 2.256). Clean sealing surface - they should be free of oil and grease.

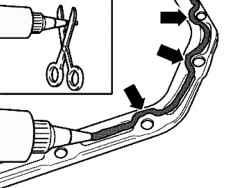

Setting Cut the tip of the tube at the front marking (F holes about 3 mm).

NOTE Follow the shelf life of the sealant. The oil pan must be installed within 5 minposle applying silicone sealant.

|

Apply silicone sealant D 176 404 A2, as shown in Figure 2.257, to clean the seating surface of the oil pallet. Bead of sealant should be 2-3 mm in thickness In places Holes, apply sealant on the inside - the arrow.

NOTE The thickness of the sealant harness must not exceed the values specified above, as excess sealant could enter the sump and clog the strainer maslozabornogo pipe oil pump. |

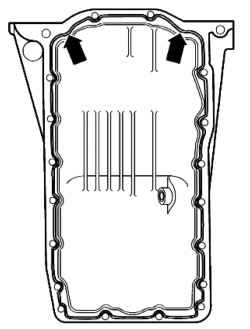

Apply silicone sealant D 176 404 A2 to clean the seating surface of the oil pan, as shown (Fig. 2.258). Immediately install the oil pan and lightly tighten all bolts. Tighten the oil pan 12 Nm.

NOTE After installation of the sump sealant must be dry in about 30 minutes. Only then can pour motor oil. Further installation and assembly is performed in reverse sequence to removal. |

|