printable version printable version

Checking injectors

Test condition The fuel pressure should be normal, check the check the fuel pressure regulator and residual pressure in the fuel system.

Checking procedure Remove the intake manifold. Then completely remove the fuel rail (fuel supply line should be left connected).

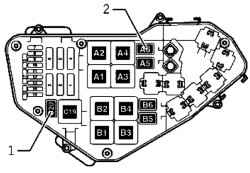

Leak test Uncover the fuse holder.

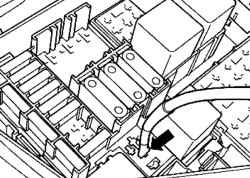

Connect the remote control for VAG 1348, VAG 1348 / 3A adapter cable VAG 1348/33 to the fuel pump relay connector module right Fuel (Fig. 2.277).

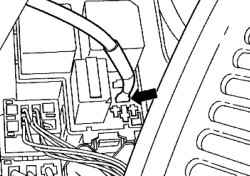

| Fig. 2.278. Cable adapter connects to the fuel pump relay

|

The second contact wire adapter - VAG 1348/33 to connect the fuel pump relay connector module fuel left (Fig. 2.278). Turn on the remote control. If the fuel pump operates, check the tightness of injectors (visual inspection). When operating fuel pumps of each injector should go 1-2 drops of fuel per minute. When leaving more fuel replace the faulty injector. Installation is carried out in reverse order. It is necessary to consider the following. The O-rings must be changed on all injectors and pre-moisten them in the engine oil. Insert injectors vertically and in the correct position into the fuel rail and fix their mounting brackets. Install the fuel rail with the injectors fixed it on the intake manifold and evenly press it.

|