printable version printable version

Checking the fuel injection quantity

Test condition The fuel pump relay and fuses 13 and 14 should be inserted in the stocks.

Checking procedure

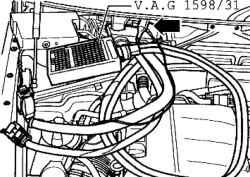

Connect adapter cable, 121-pin VAG 1598/31 sockets and Jumper Switch 1 and 65 of a set of wires VAG 1594C (Fig. 2.279). Insert the nozzle in a test measuring vessel injection quantity tester VAG 1602.

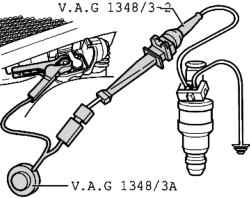

Connect one contact of the test injector via wires from a set of auxiliary measuring devices VAG 1594 / C to the mass of the engine (Fig. 2.280). The second contact plug nozzle via the auxiliary wires to the panel control for VAG 1348 - VAG 1348 / 3A with a wire-adapter - VAG 1348/32. Clamp type "crocodile", connect the positive terminal of the battery in the engine compartment. Operate the remote control 30. Repeat the operation with the remaining nozzles. For each injector, use a separate tube. After testing all the nozzles set measuring container on a flat surface and compare the amount of fuel. Specification: 128-140 ml per injector. For a nominal value or has not been reached or exceeded by one or more nozzles, replace the faulty injector. Installation is carried out in reverse order. It is necessary to consider the following. The O-rings must be changed on all injectors and pre-moisten them in the engine oil. Insert injectors vertically and in the correct position into the fuel rail and secure their mounting brackets. Install the fuel rail with the injectors fixed it on the intake manifold and evenly press it.

|