printable version printable version

Removing and installing engine control unit with protection against theft

NOTE If necessary, replace the engine control unit, connect the diagnostic tester VAS 5051B and perform slave function ?«Motorsteuergeraet ersetzen / Control Module Replacement." |

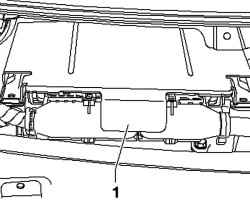

Withdrawal Switch off the ignition. Remove the wiper arms. Remove the liner plenum chamber.

NOTE Thread Stall threaded screw is covered with varnish. By heating shear screws with a hair dryer binding effect lacquer thread decreases. |

ATTENTION To avoid damage due to burning, cover the wires, plugs and control units in the vicinity of the engine control unit. |

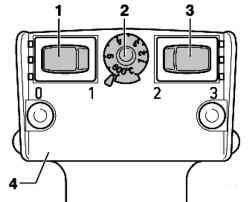

Make settings dryer 4, as shown in Figure 2.284. Turn the temperature adjustment potentiometer 2 at maximum heating power (600 ?° C). Give a two-stage switch the amount of air in the 3 position 3.

ATTENTION Due to the shear heating of screws and very hot part of the protective housing. to avoid injury, wear protective gloves. |

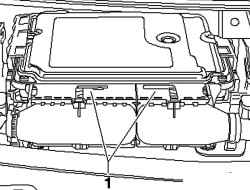

Aim the nozzle dryer at the stall screw. Turn on the hair dryer and warm up the screw head approximately 20-25 seconds. Remove the screw stall 2 ticks per head. A process similar to the second screw loosening.

Slide the connectors on the control unit 1 to the edges of the engine and disconnect the two plugs (Fig. 2.286). Remove the engine control unit.

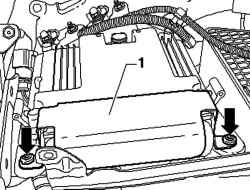

Setting Insert the engine control unit in the mounting frame in the plenum chamber. Connect the plugs to the engine control unit and slide the latches 1 to the middle.

Put the lid 1 on the engine control unit and from the hand screw the new shear screws (Fig. 2.287). Tighten new shear screws evenly until heads shear off. Install trim plenum chamber. Install the wiper arms.

|