printable version printable version

Removing and installing drive plate

Withdrawal Remove the engine. Disconnect the engine and gearbox.

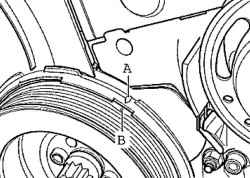

Bring engine to TDC. To this end, slots A and B must be on the same level (Fig. 2.99).

NOTE To turn the engine follows the central bolt of crankshaft. To turn the engine is permitted only in a clockwise direction. |

NOTE For a threaded plug in the crankshaft, is opening TDC (tangible hand). |

Loosen the screws crosswise drive plate and unscrew them. Remove drive plate with shim washer and compensation.

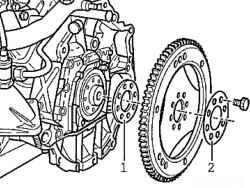

Setting Install in reverse order, with the following should be considered: Put shims 1 (thickness: 3.4 mm) to the crank pin of the crankshaft.

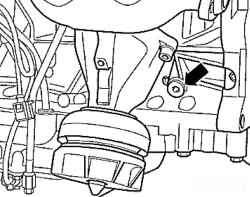

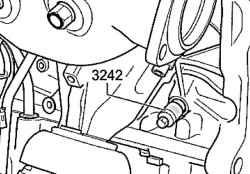

Then install the drive plate with the washer 2 (thickness: 1.5 mm) (Fig. 2.102). Insert the new retaining bolts and tighten them by hand. Tighten bolts with a torque of 30 Nm + 1/4 turn (90 ?°) (dotyazhka can be performed in several stages). Remove the locking bolt 3242. Tighten the screw plug with a new seal. Torque: 35 Nm

|