printable version printable version

Balancing

Before balancing must meet the following conditions. The inflation pressure must be normal. The tread pattern must not be one-sided wear, and its depth should be at least 4 mm. In the bus there should be no damage, such as cuts, punctures, foreign objects, etc. Wheel suspension, steering tie rods, including shock absorbers must be in perfect condition.

Test drive before balancing If an authorized vehicle enters the station to complain about the "harshness progress" before balancing should be required to take a test ride. This wizard should be familiar with the nature of the fault. The movement should be set, at what speed there is an imbalance. Immediately after the test drive lift the car on a lift. Mark a place on each tire installation. Remove the wheel and Balance the wheel.

Balancing on a stationary balancing machine Clamp the wheel on the balancing machine.

NOTE It must be remembered. Balancing wheels, as with any other repair, the most important rule is cleanliness. Just follow the cleanliness, you can achieve a perfect result. Dirt and rust in the fit and centering holes distort the result of the wheels. |

Before you install the wheel on the balancing machine, clean the contact surface, centering the hole and drive. Install the tire and wheel on the balancing machine.

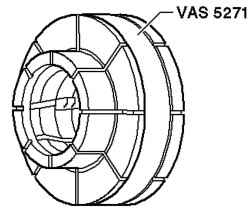

NOTE To tighten the wheel use, for example, samorazzhimayuschiysya collet adapter for balancing stands VAS 5271 (Fig. 4.13). |

When using it, guaranteed 100 percent alignment of the wheel clamp and careful drive. Tapered centering adapters do not provide 100 per cent alignment of the wheels on the stand. If you deviate from the center by 0.1 mm at the wheel and the tire comes in 10 gram imbalance.

The procedure works when balancing wheels / tires Scroll wheel with tire on the balancing machine. Check the course of marking strips on the sides of the tire in the rim contour. Check the tread during rotating wheel.

NOTE When unilateral wear, spots wear due to braking with locked wheels or strong irregular wear to achieve balanced ride fail. In this case it is necessary to replace the tire. |

Check the accuracy of the wheel speed with the tire. If the tire and wheel rotates smoothly, although flattening tires not, the reason for this may be the radial and lateral runout. Check drive bus for the presence of radial and lateral run-out. If the radial and lateral runout are within tolerance, Balance the tire and wheel.

NOTE Do not use more than 60 grams of weight per wheel. If more weights, then if necessary to achieve a good balance by minimizing. |

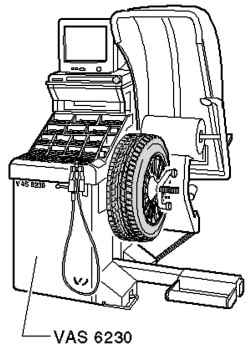

Minimization The display balancer to be displayed 0 grams. Alternatively, you can minimize the use balancer VAS 6230. Fasten the wheel to the hub. First tighten the lowest wheel bolt to approximately 30 Nm. Then, tighten the remaining screws and 30 Nm crosswise. In this way, the wheel is centered on the hub. Lower the car on wheels. Now tighten the wheel bolts crosswise with a torque wrench at the specified torque. After balancing the wheel, do a test drive. If the driving experience still felt the beating, it could be because the balancing error due to wheel alignment. Errors centering wheels and hubs in adverse cases may overlap. For this reason, it is also possible runout. It can be eliminated with the help of the stand for the final balancing.

Balancing control stand VAS 6230

With control of the balancing stand VAS 6230, in addition to the well-known static balancing, you can perform additional functions (Fig. 4.14). A feature of this system is to check the wheel radial force with the tire during rotation. During this test, the roller presses on the wheel with a force of about 635 kg. Thus, the simulated force acting on the supporting surface of the wheel from the road surface during driving. Because the radial and lateral runout in the tire and wheel and the different stiffness of the tire force. acting on the contact area of the tire change. System VAS 6230 recognizes and remembers the position of the maximum measured radial force of the tire. With this measure the position of the smallest distance between the rim flange and the center of the disc.

|