printable version printable version

Repair of control system clearance

Perform the following test under specified conditions. The vehicle must be cold, it is moved when checking is not permitted The room temperature must be 10-30 ?° C, while the temperature difference should be minimal. The car should be on an equal basis. Start the engine. Use the front display and control unit J523, set a high level of body, and then normal. Turn off the engine. Remove the plug from the control unit regulation clearance J197, to exclude the possibility of regulation.

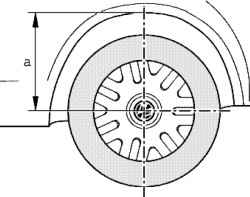

Measure the height of the vehicle at all four wheels (Fig. 4.38). After 2 hours, measure the height again and compare the size of a to the result of the first measurement. If the vehicle is not level, this means that there is an air leak in the suspension of the wheel, where there is the maximum difference between the first and second metering. With conventional spray to find leak check the appropriate air line and pneumatic components in the following sequence. If after 2 hours to install the difference persists, repeat the test after 24 hours. After 24 hours, the difference may be up to 4 mm. Check out: - Air duct connection; - Residual pressure valve; - Front pnevmoelementy (without dismantling), rear pnevmoelementy (dismantling). When defective shock absorbers oil from them may fall into the pneumatic system. For the impeccable work of the pneumatic system after the fault must be cleaned or replaced by other ingredients. Unscrewing the air line from the air element and the block of solenoid valves. Purge the pipe several times with compressed air, this compressed air supply through the end of the pipeline, which is attached to the solenoid valves. Check whether the oil got the shock absorber unit solenoid valves. If the unit has got the shock absorber solenoid valves oil block to be replaced. Check the internal air line between the compressor and the valve block. If the internal air line has got oil, will have to replace the compressor.

|