printable version printable version

Removal and installation of the compressor unit without solenoid valve

Withdrawal Remove bottom right trim.

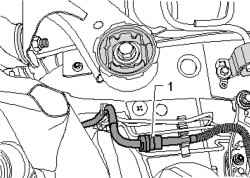

Disconnect the electrical connection between 1 and 2 and the compressor body.

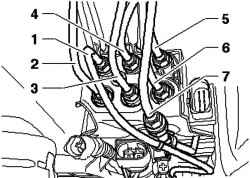

| Fig. 4.42. Airway tube: 1 - black, inner conduit between the power of the solenoid valves and compressor; 2 - green, the air line to the front right elastic Pneumoelements; 3 - red, the air duct to the rear left elastic Pneumoelements; 4 - purple, the air line to the front left elastic Pneumoelements; 5 - blue, the air line to the accumulator; 6 - yellow, the air line to the right rear elastic Pneumoelements 7 - brown, the air line connections for tire inflation

|

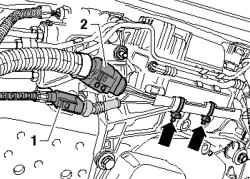

Remove the air duct 1 from the solenoid valve block (Fig. 4.42). Disconnect the pipe from the coupling 7.

ATTENTION To remove the air lines 2 through 6 are not permitted. |

Remove the air lines from the holder on the bottom. Remove the nuts A compressor.

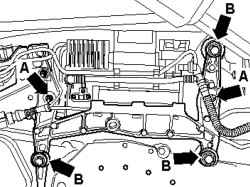

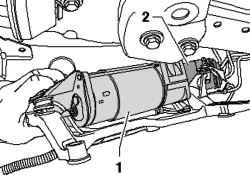

Remove the bolts B, then the assistant should secure the compressor to the holder (Fig. 4.43).

Compressor with lower holder forward so that the compressor 1 can be removed (Fig. 4.44).

ATTENTION Make sure that the solenoid valve block 2 has been removed from the bottom as low as possible. In addition, in any case not allowed to bend or stretch of air. |

Setting Installation is carried out in reverse order.

Tightening torques Air pipes to block solenoid valves: 4 Nm. Holder to the body: 20 Nm. Compressor to the holder 6 Nm.

|