printable version printable version

Removing and installing drive plate

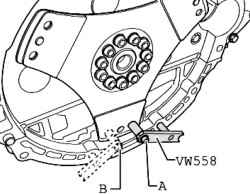

Counter support for the VW clutch 558 tighten with an Allen bolt M8h50 on the slave drive (Fig. 2.166). Between the counter support and the driven disc set of three hexagonal nuts M12. Position counter support: And with the weakening, in tightening Installing the drive plate Install the clutch disc using the washer. Install new bolts and tighten to a torque of 30 Nm.

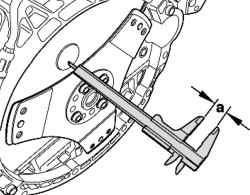

| Fig. 2.167. The distance between the drive plate and the cylinder block

|

Check with calipers the distance between the drive plate and the cylinder block (Fig. 2.167). Setpoint A: 20.6 mm. If the specified value is not reached: Remove the clutch disc and install the shims between the drive plate and the crankshaft. Retighten the bolts to 30 Nm. Tighten bolts to 50 Nm and make more 1/4 turn (90 ?°), dovorachivanie can be carried out in several stages.

|