printable version printable version

Removal and installation of the slide valve box

Spool box and / or tubes can be removed / installed as specified in the gearbox, and when removed.

Withdrawal If the operation is not yet complete - remove the oil pan and the oil strainer

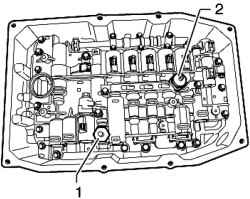

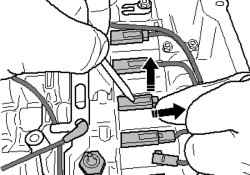

Carefully remove the plugs for the hydraulic pressure sensor 1 in the ACP G1931 and hydraulic pressure sensor for the automatic transmission 2 G1942 (Fig. 3.73).

| Fig. 3.77. The oil temperature sensor Gearbox

|

Oil temperature sensor Gearbox G93 tightened to a torque of 10 Nm (Fig. 3.77).

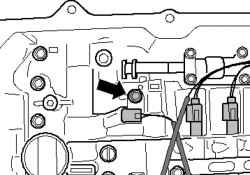

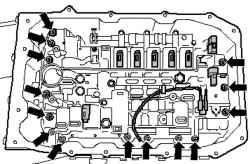

Unscrew the bolts slide valve boxes "criss-cross" (Fig. 3.78). Torque: 8 Nm + 90 ?°.

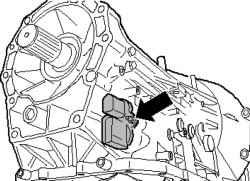

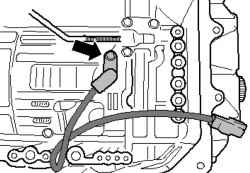

The sensor output speed gearbox G195 is tightened to a torque of 10 Nm (Fig. 3.79). Installation is carried out in reverse order. After installation fill the ATF, and then check the level of ATF, if necessary - add oil

|