printable version printable version

Removing and installing the gearbox, cars with petrol engines V6 and V8, turbodiesels V6 TDI, V10 TDI and W12 engine petrol

Short description Automatic gearbox 09D is removed together with the motor, the front main gear and transfer case. In the Touareg with any versions of the engine is recommended before removing the power unit to dismantle the lower connecting bolts "of the engine / transmission. If possible, pre-set torque converter. This council acts as during removal, and when connecting the transmission to the engine. There are two variants of the engine disconnected from the gearbox on the pasteboard VAS 6131.

First option Automatic gearbox 09D and distributing gearbox 1 are screwed to each other. These units can be removed together from the engine for example, removing or installing the converter. The front propeller shaft 2 just spun in front of the transfer case. Thus it is possible to separate the motor on one side and the other side of the box on the mounting table VAS 6131 apart.

Second Embodiment First off the table remove the transfer case, then automatic transmission. Thus it is possible to carry out assembly work on the automatic transmission. To do this, you must first unscrew the front propeller shaft on both sides, the transfer case 1 is disconnected and removed from the table. Only then disconnect the automatic transmission from the engine and, if necessary, also removed from the table. This second embodiment is described below.

Withdrawal In all variants of the engine is recommended before removing the power unit to remove the lower connecting bolts the engine / gearbox. If possible, set the torque converter as soon as possible.

Removing the engine from the gearbox (cars with petrol engines V6 and V8)

Remove the torque converter from the drive plate.

Vehicles with turbo diesel engine V10 TDI In these vehicles mounting the torque converter connecting bolts and lower the engine / gearbox must be mounted during a power unit.

NOTE Filming starter cable can not be loosened until the connecting bolt (Fig. 3.51). |

Vehicles with V6 TDI turbodiesel engine Remove the starter can not be installed until the torque converter bolts.

Continued for all vehicles

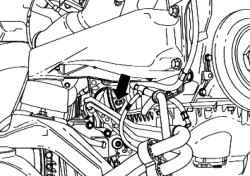

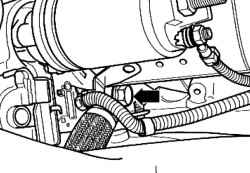

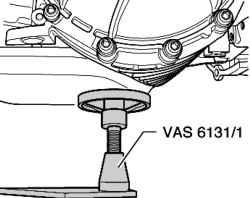

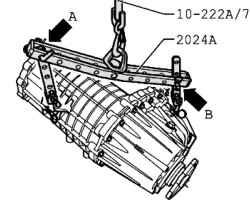

Make sure that the support for automatic transmissions were mines. 2 plates VAS 6131/1 timeline under the oil pan (Fig. 3.52). Remove the propeller shaft between transfer case and front drive with transfer case. To keep the propeller shaft can use the support T10172.

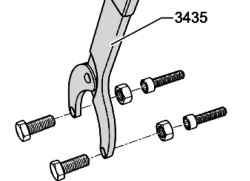

Also, to support the 3435 fit the 2 screws max. M10 (Fig. 3.53) or This protection against T10172.

Remove the transfer case and put aside.

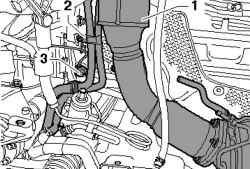

Vehicles with V6 TDI turbodiesel engine Remove the catalytic converter and the particle filter 1 with a turbocharger. Always replace the nut on the turbocharger. Remove the tube cooling system 2 with a converter housing 2 bolts.

| Fig. 3.55. The catalyst tubes of the cooling system and the speed sensor

|

Remove the tube ATF. If this operation has not yet been done - it removes the heat shield on the left gearbox. Further, when disconnecting the engine V6 TDI from the gearbox, make sure that the engine does not stall down. Therefore, raise the engine using a crane VAS 6100 and accessories for hanging 3033. Install faucet on the side of the table. If there is no second crane, remove the engine and gearbox, and then to base engine with the appropriate means.

Vehicles with W12 engine Remove all of the catalysts to the exhaust manifold. Remove the tube ATF. If at the beginning of the dismantling of the power unit, this operation was not performed, remove the converter from the drive plate.

Continued for all vehicles Before disconnecting the engine from the gearbox, take measures to ensure that the engine is not turned over. This operation will be shown again on the example of the engine V6 TDI. If there is no second crane, remove the engine and gearbox, and then to base engine with the appropriate means. Lift the transmission with a crane. Remove the tube ATF. Remove all connecting bolts the engine / gearbox. Carefully push the transmission from the engine. Make sure that the torque converter gearbox was pinned drive plate.

Setting Installation is carried out in reverse order. Check the adjustment of the selector rod, if necessary, adjust. After installation, check the level of ATF, if necessary, add oil and make wheel alignment.

|