printable version printable version

Removing and installing control unit of an automatic transmission J217

Withdrawal Before removing the control unit of an automatic transmission J217 must first ask for the identity of the control unit and character of the old unit.

NOTE To avoid damage to the front pad under the right front seat, trim tabs are shown in Figure 3.62. |

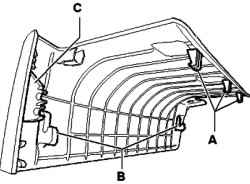

Catches And cling to the transverse stretching under the seat. Gently push down the cover and slide it back simultaneously. Hold the cover in position and locks in A pull it up to unlock. Catchers get in the grooves in the transverse stretching in front of the seat. Unlock they can also be by pushing down and pulling forward. Zaklipsovany lock with a side seat cover by pulling them forward, you can trim rasklipsovat. Set the seat to the back, the top position. Unlock clips ?«A?» by pressing down and sliding the back simultaneously. In this position, hook fasteners in trim ?«A?».

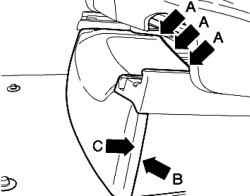

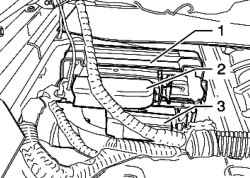

Push cover down while pulling it forward. In this release the lock ?«B?» and ?«C?» (Fig. 3.63). Set the seat to the front, the top position. You should always observe the sequence off of the battery. Turn off the mass terminal of the battery when the ignition is off. The housing 1 is a control unit J217 Automatic gearbox control unit and transfer case J646.

Unlock and remove the plugs of the control unit 2 J646 transfer case and the plug of the control unit of an automatic transmission J217 3 (Fig. 3.64).

Remove the bolt 1 and remove the housing with the control units of the attachment (Fig. 3.65).

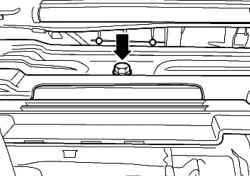

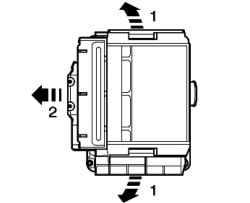

1 Pull the latches out, and remove the control unit from the housing 2 (Fig. 3.66).

Setting Installation is carried out in reverse order. It is necessary to consider the following. Check the old coding and code new control unit. Install the seat trim. Perform work steps after connecting the battery.

|