printable version printable version

Processing valve seat

NOTE When repairing engines with leaky valves treat or replace the valve seats and valve insufficiency. Particularly in engines with long service life, check the valve guides for wear. |

Valve seats should doobrabatyvat just enough to achieve the kind of perfect work surface. Before treatment should risschitat maximum allowance for processing. If you exceed the allowance for processing may be impaired function of the hydraulic control valve clearance (lash), which would entail the replacement of the cylinder head. Remove the camshafts. Calculate maximum allowance for processing as follows: - Insert the valve into the guide and press it firmly to the saddle;

NOTE If the valve is replaced during repair, then the measurements should use a new valve. |

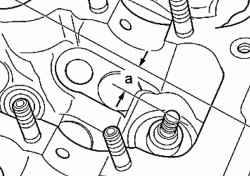

| Fig. 2.85. A distance between the end of the valve stem and the upper edge of the cylinder head

|

- Measure the distance A between the end of the valve stem and upper edge of the cylinder head (Fig. 2.85); - Calculate the maximum allowance for processing on the basis of the measured distance A and the minimum size.

Minimum dimensions

Measured the distance A minus the minimum size = max. allowable size refinement. Example: Measured distance 10.6 mm ..... The minimum size of 10.2 mm ..... The maximum allowable allowance for processing ..... 10,6-10,2 = 0,4 mm

NOTE The following diagrams the maximum allowance for processing valve seats depicted as size B. |

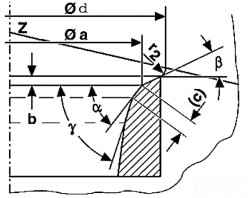

Processing inlet valve seat

| Fig. 2.86. The processing circuit inlet valve seat

|

a - ZH30,6 mm b - the maximum size of finishing c - 0,9-1,5 mm d - max. ZH35,0 mm r2 - radius of 2.0 mm Z - lower edge of the cylinder head a - 45 ?° chamfer angle of the valve seat b - 30 ?° angle correction chamfer the top g - 60 ?° lower correction angle chamfers

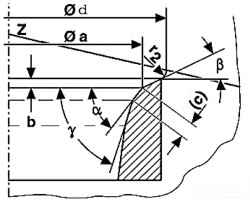

Processing saddle valve

| Fig. 2.87. The processing circuit of the exhaust valve seat

|

a - ZH26 mm b - the maximum size of finishing c - 1.2-1.7 mm d - max. ZH29,0 mm r2 - radius of 2.0 mm Z - lower edge of the cylinder head a - 45 ?° chamfer angle of the valve seat b - 30 ?° angle correction chamfer the top g - 60 ?° lower correction angle chamfers

|