printable version printable version

Replacement of sealing flange on the side of the crankshaft vibration damper

Withdrawal Result a radiator framework in service position. Remove ribbed belt. Remove the vibration damper. For this secure vibration damper with a key to lock the T10069. Remove the oil pan. Remove the mounting of the sealing flange. Remove any residual sealant from the sealing surfaces.

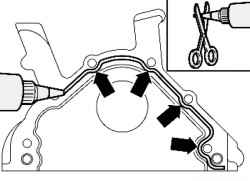

Setting Remove the remaining oil on the crank pin of the crankshaft with a clean cloth. Cut the tip of the tube on the front mark (O holes about 3 mm).

Apply a bead of sealant thickness of about 2-3 mm, as shown in Figure 2.50 on the clean surface of the sealing flange.

NOTE Before applying the sealant gland cover with a clean cloth. The sealant layer should be no thicker than 2-3 mm, because otherwise the excess sealant may enter the sump and clog the strainer in maslozabornom nozzle. Observe the shelf life of the sealant. The sealing flange must be installed within 5 minutes after the application of the silicone sealant. |

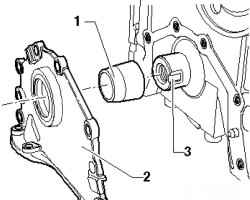

Install the guide bushing 1 T10215 / 1 on the front of the neck of the crankshaft 3.

| Fig. 2.51. Installation of a sealing flange with oil seal

|

Then gently insert the flange sealing gland 2 through the guide sleeve (Fig. 2.51). Screw the flange of the cylinder block. Install the oil pan.

NOTE Fixing bolt vibration damper should be replaced. |

Tighten the fixing bolt with a torque wrench VAG 1601. Install vibration damper and lock it counter support T10069. Tighten the new fixing bolt torque of 100 Nm + 1/4 turn (90 ?°). Install poly V-belt.

|