printable version printable version

Removing and installing drive plate

Withdrawal

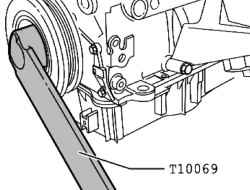

Remove the clutch disc. For this secure vibration damper with a key to lock the T10069 (Fig. 2.42). Loosen the fixing bolts slave drive crosswise and unscrew them. Remove the clutch disc.

Setting Screw the drive plate to the crankshaft at least three old mounting bolts, tightening them to 30 Nm.

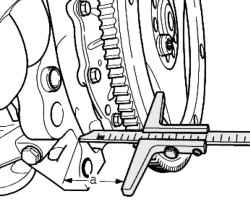

| Fig. 2.43. Measure the distance from the surface of the flywheel housing to the cylinder

|

Measure the size of a depth gauge (Fig. 2.43). Specification: 21,0-23,0 mm

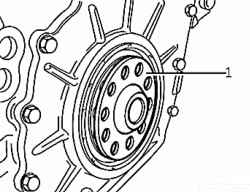

If the actual value is lower than the nominal again remove the clutch disc and use the appropriate compensating washer 1 (Fig. 2.44).

NOTE To align allowed to use shims of appropriate thickness only. |

If the actual value is equal to the nominal insert the new fixing bolts and tighten them by hand. Tighten the fixing bolt with a torque of 60 Nm + to tighten 1/4 turn (90 ?°) (dotyazhka can be performed in several stages).

|