printable version printable version

Removing and installing cylinder head cover

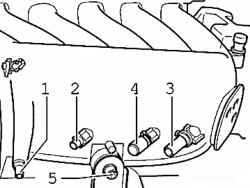

Withdrawal After installation, you must reinstall all fasteners cable, remove or cut during removal. Remove the engine cover. Remove ignition coils with output stages. Remove the hose between air mass meter G70 and the throttle control unit. Disconnect the 6-pin connector from the control module throttle J338, as well as 2-pin connector of the solenoid valve 1 activated charcoal canister N80 and crankcase ventilation valve. Disconnect vacuum hoses from an inlet collector 1-3. On cars with the letter designation of the engine BAA and BMX additionally remove the vacuum hose from the intake manifold 4.

| Fig. 2.56. Fixing bolt intake manifold support

|

Remove the mounting bolt 5 supports the intake manifold (Fig. 2.56). Then, unscrew the mounting intake manifold right and left at the collector. Disconnect the hose crankcase ventilation of the cylinder head cover.

| Fig. 2.57. Fixing bolts of the intake manifold

|

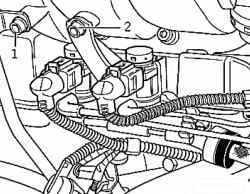

Loosen cap screws 1 and 2 in the intake manifold (Fig. 2.57). Disconnect the vacuum hose from the vacuum actuator switching intake manifold. Remove the intake manifold from the cylinder head. Remove the inlet pipe and place it on a clean surface so as not to damage the vacuum actuator element.

NOTE The inlet channels in the inlet manifold and the cylinder head should be covered with a clean cloth. |

The front of the cylinder head cover unscrew the wire to the knock sensor 1 and sensor G61 level and oil temperature G266. Remove the cylinder head cover.

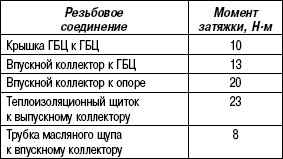

Setting Installation is performed in reverse sequence, with the following features. The intake manifold must first be bolted to the cylinder head. Then tighten the two screws and bolts the heat shield backups inlet. Check the tightness of fastening the fuel hoses.

Tightening torques

|